Overview

Founded in 2011, JNTG inherited the research and development that had been going on since 2006 from its parent company, JNTC. Leveraging such distinctive technological expertise, JNTG is now leading the market for materials and components for fuel cells that are used to produce hydroelectric cars and power generation systems.

Since 2003, we have diligently pressed on with the R&D of the 'gas diffusion layer' (GDL), a critical component of fuel cells. Thanks to this effort, we successfully commercialized our first GDL product in 2013. Our heavy investments in production facilities allowed us to become the first Korean company that has independently developed and localized the ability to manufacture GDL in continuous production.

Back in 2008, when we began working on GDL in earnest, there was no production base in the country for carbon fiber. This was a problem, since carbon fiber is the main material for making GDL. There was no experience to go around that could assist the development and manufacture of carbon paper that was needed to make the GDL or its backing layer. Through many trials and errors and incredible persistence in research, JNTG successfully developed our very own carbon paper. Furthermore, we leveraged the GDL technology that we gained to start another project making 'carbon felt electrodes,' which could be used to make vanadium redox flow batteries in energy storage systems. This, too, resulted in a successful commercial product.

JNTG is poised to become the GDL supplier for domestic hydroelectric cars in Korea. It has also been acclaimed for its competitive products and technology when it became a GDL supplier to major Chinese automobile manufacturers in 2017.

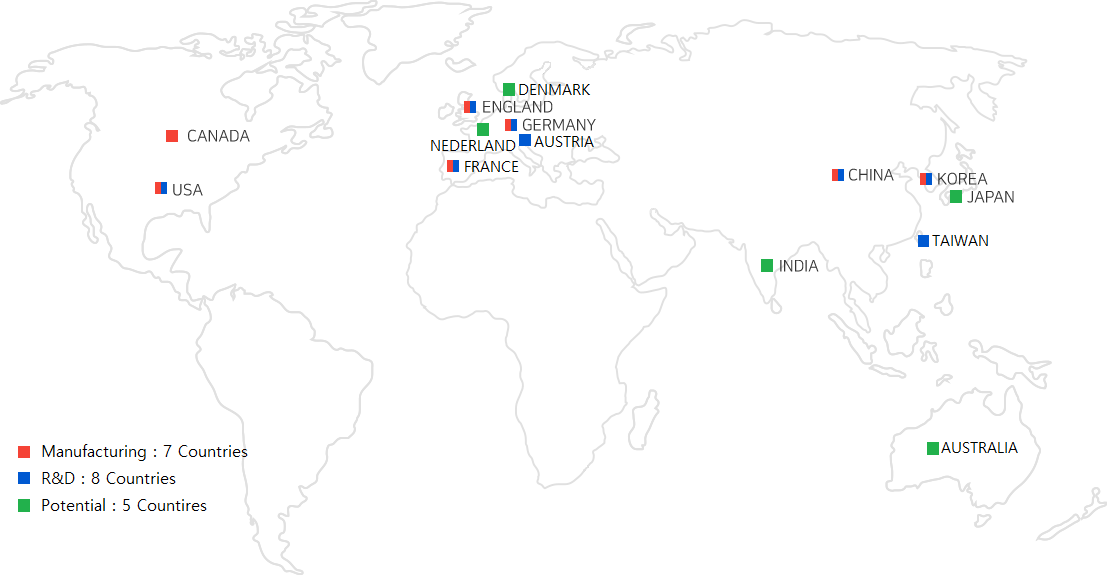

JNTG is committed to continuing investments and technological acquisitions in the field of fuel cell development. Possible applications not only include hydrogen fuel cell vehicles and stationary fuel cells, but also water electrolyzers, energy storage systems (ESS), and any other system that involves electricity. We are committed to leading the effort to develop and supply the global market with environmentally friendly, highly efficient fuel cells that leverage our most advanced technology.

Established

2011

Revenue

22 billion KRW

Employees

92

Annual Production Capacity

45,000 units for automobiles

Main Products

Our GDL features uniform thickness, ease of material transfer, and low electrical resistance, making it a highly durable product that is well regarded in markets both at home and overseas.

(Graphite Felt Electrode)

In one project, we are seeking to develop a superior structure

for the GDL based on the gas diffusion backing layer (GDBL).

Our Customers

Revenue

(Unit : KRW 100 million, Separate Statements)

Revenue share

(by Business Area)