GFE (Graphite Felt Electrode)

At least 99% carbon content. Highly durable in prolonged driving conditions. High electrical conductivity.

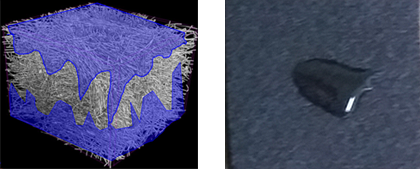

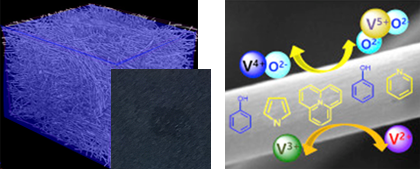

The GFE (Graphite Felt Electrode) is an important component of energy storage systems (ESS). It provides the reaction site

(or catalyzes) the vanadium ion's redox reaction. It also provides an electrical connection between the catalyst layer and separator plate, serving as an important component that enables electron transport.

A flow battery is a rechargeable battery in which the reactive electrolytes are supplied to the stacks from the electrolyte tank. JNTG's specialized surface treatment technology allows our GF electrodes to have a high graphite degree, resulting in excellent performance and durability.

Our GFE undergoes a graphitization process that give it at least a 99% carbon content. It displays high durability in prolonged driving conditions and high electrical conductivity. We can deliver products in sheet or roll form. We can also control their thickness and density, optimizing them for the particular structure of the VRFB system the customer needs. The GFs do have to become thinner as part of improving the energy density of stacks. The thin-film (1mm) graphite felt is currently in development.

Features & Specifications

- Various thicknesses available (2.5 mm – 7 mm)

- Excellent performance by thermal and chemical activation

- High durability and excellent quality uniformity for mass production technology integration

-

Thermal Treatment (Competitor)

Resin absorption is uneven across and below the surface

Overoxidation of GF surface reduces durability -

-

Thermal & Chemical Treatment (JNTG)

Uniform levels of oxidation and resin absorption across and below graphite felt surface

Highly durable, high voltage efficiency

| Model | Thickness (mm) |

Areal Weight (g/m²) |

Carbon Content (wt.%) |

Electrical Resistance(TP) (mΩ∙cm2) |

Graphitization |

Functionalization |

|---|---|---|---|---|---|---|

| GF031BH | 2.5 ± 0.5 | 230 ± 40 | ≥ 99.0 | < 230 | O | |

| GF051BH | 4.2 ± 0.5 | 400 ± 50 | ≥ 99.0 | < 180 | O | |

| GF061AH | 5.0 ± 0.5 | 500 ± 50 | ≥ 99.0 | < 180 | O | |

| GF072A | 7.0 ± 0.6 | 840 ± 135 | ≥ 99.0 | < 180 | O | |

| Remark | @ 1kPa | @ 900℃, Air | @20% compressed |

* Standard size:

GF072A - (width) 750mm

GF072A and other models – (width) 600mm

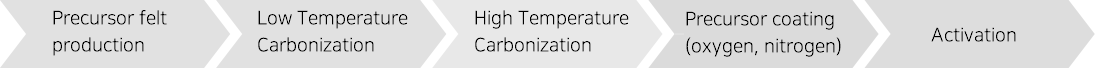

Production Process

- In-house carbonized felt production allows us to control thickness, weight, etc.

- The simultaneous use of chemical and thermal activation techniques allow us to activate the carbon uniformly both on and below the surface

- Our experience with making products in various sizes puts us in an excellent position to supply materials for stack production

* Each step is completed from roll to roll.

Activation

Energy Storage System (ESS)

Redox Flow Batteries

Zinc-Hybrid Batteries

Library